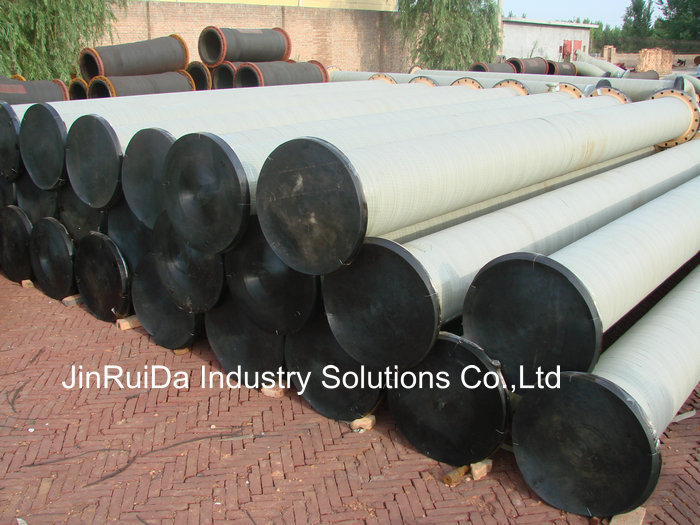

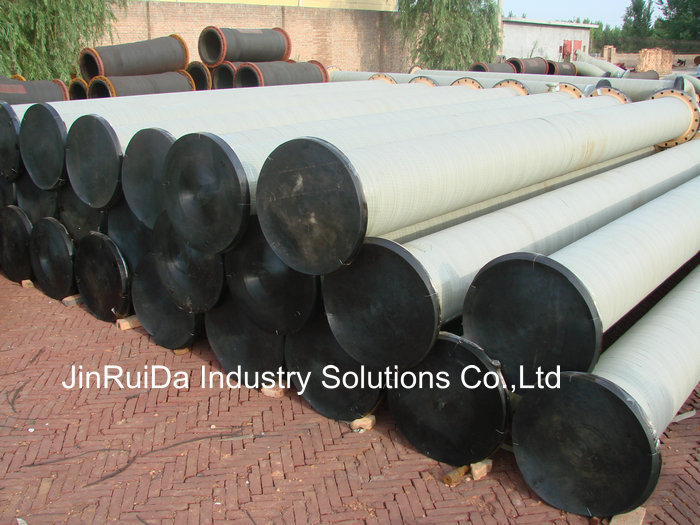

Mining Rubber Hose ( Rubber Flexible Hose )

Mining Rubber Hose ( Rubber Flexible Hose ) Are Made Of Multi Rubber Layer And Metal Tensile Steel Wire Reinforcement Layer, Sometime Use Nylon Enhancement Layer Instead.

The Wear Resistant Rubber Layer Is The Innermost Layer. Be Abrasion Resistant And Wear Resistant To Medium.

Metal Framework Layer Should Be Stainless Steel Wire Skeleton. So That Make It Into Rubber Metallic Bellow

The Framework Flexibility Make Sure Mining Rubber Hose Be Flexible, Protect Rubber Mining Hose From Sagging When Destroying Load And Pressure

The Reinforcement Layer Is Made Of Stainless Steel Wire Or High Strength Curtain Fabric, Withstand Fluid Static Pressure During Operating

The Bonding Layers Are Bonded With The Rubber As An Integral.

The Heat Preservation Layer Is Provided With Energy-Saving Heat-Preservation Material. The Thickness May Be Designed Depending On The Customers’ Requirements.

The Outer Protective Layer Is Designed According To Heat-Preservation Layer As a Protective Case,

Materials Is Woven With Stainless Steel Wire Or The Other Super High Molecular Non-Metallic Material.

Features:

(1) Good Flexibility And Impact Resistance

The Rubber Mining Hose Is Good Bending, High Strength, Rigidness, And Impact Resistance. It Is Low Linear Expansion Coefficient And Creepage Resistance As Similar As Steel Pipe, The Internal Lining Material Has The Best Impact Resistance And Absorption Performance Of Plastic, Of Which Flexibility Can Greatly Provide Reliability Of Transferring System.

(2) High Wear Resistance

The Wear Resistance Is Higher Than That Of Steel Pipe, Stainless Steel Pipe, Wear Resistant Metallic Spraying By 4-7 Times. It Is More Ideal To Transferring Raw Salty Materials For Such Small Sized Slurry As Power Coal Ash, Water Coal Slurry, Tailing Ore Etc., Which May Greatly Prolong Service Life Of Hose And May Enhance The Transferring Efficiency By 20% Or So.

(3) Wide Range Of Applicable Temperature:-50℃ - 95℃.

(4) High Tensile Strength: The Connecting Points Of The Rubber Mining Hose And Fittings Are Provided With Lifting Rigs For Hose Distribution.

(5) Scale-Inhibiting And Energy-Saving

Good Lubrication And Non-Adhesive May Uneasily Result In Scale. The Flow Resistance Is Very Small Due To Corrosive And Wear Resistance As Well As Without Scaling On The Inner Wall Of Hose. It Features Small Friction Coefficient. It May Keep Constant Flow Velocity And Flow Rate, Of Which Inner Wall Diameter Is Designed To Lower Than That Of Steel Pipe By 150%. Especially, It Is Suitable For Transferring High-Viscosity Slurry Mixture And Easily Scaling Power Materials.

(6) Corrosion Resistant And Anti-Aging

It Is Unnecessary To Apply Corrosion Protection Coating Materials During Construction Of Hose. It May Be Resistant To Erosion Due To Many Kinds Of Chemical Medium Except For Several Medium. Apply Oxidization Inhibitor And Carbon Black Uv Absorbent Into The Formulation Of Raw Material To Feature Outstanding Anti-Aging Performance And Good Weather Resistant Performance. It Features Strong Weather Resistant And Anti-Aging Performance Due To Stability Of Properties.

(7) Easy Installation

The Mining Rubber Flexible Hose Has Good Flexibility, Of Which Is Only 1/6 Of That Of Carbon Steel Pipe Or Stainless Steel Pipe. It Is Very Easy To Loading/Unloading, Transportation, Installation And Use. It May Accommodate All Kind Of Ground Foundation. It May Be Directly Bent To Be Laid, With Easy And Simple Connection, Which May Greatly Save The Consumption Of Labor Force And Material In The Process Of Installation.